MDG has state-of-the-art laser scanning technologies & is a full service metallurgical lab that further demonstrates the unwavering commitment to quality. A key component to the tooling manufacturing process is the rapid, high accuracy measurement of tool & die parts. With the state-of-the-art computerized tooling inspection and measurement resources, enable us to produce the most precise, effective tools on the market. We are able to validate parts with or without a checking aid. Also have the ability to conduct gauge studies, repeatability checks, production part approvals and trim development validation. If reverse engineering is needed, we have that ability through laser scanning to create digital data, to generate a mesh and/or modify surfaces.

Our full service metallurgical lab includes the following metrology equipment:

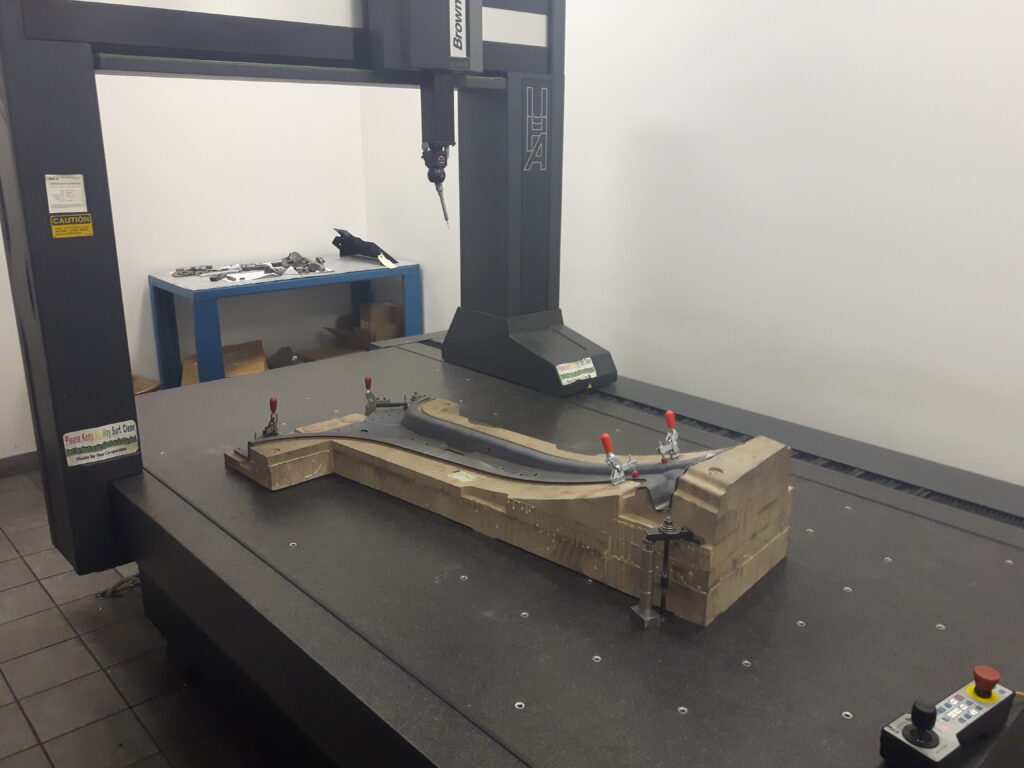

- Coordinate Measuring Machines (CMM)

To ensure the most accurately sized tools are produced for a customer’s application. - 3DLight Optical Scanner

Useful when needing to measure numerous points, or to access larger and immobile components.

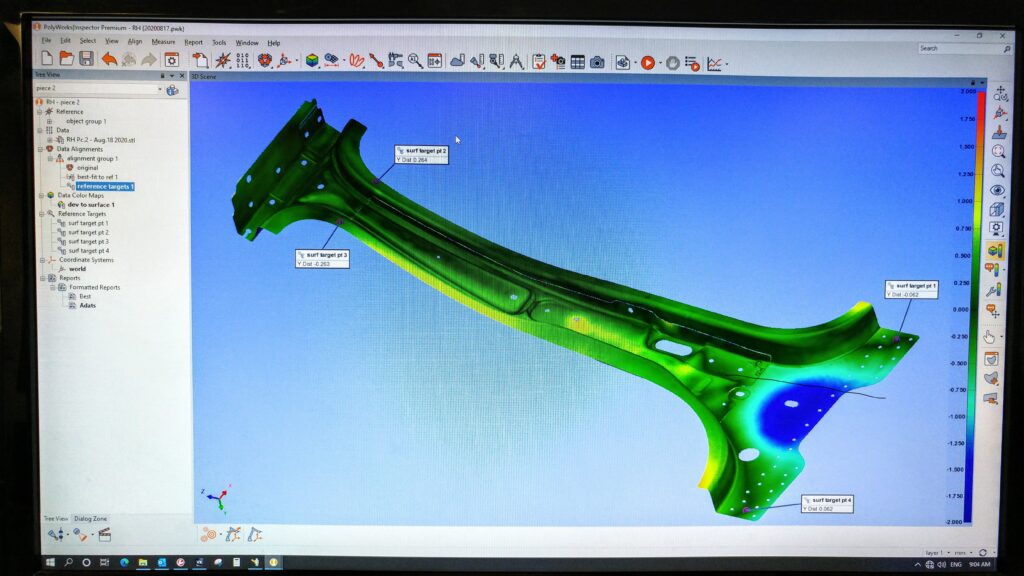

This equipment enables us to inspect all aspects of the tooling systems produced. This also verifies that complex parts are geometrically precise and created exactly to the correct specifications. MDG’s software systems employ diverse reporting capabilities, so that detailed reporting can be provided on the inspection of the tool & die parts throughout the manufacturing process.

Using a 3D Light Scanner to measure the geometry of a part to determine if it is to specification.