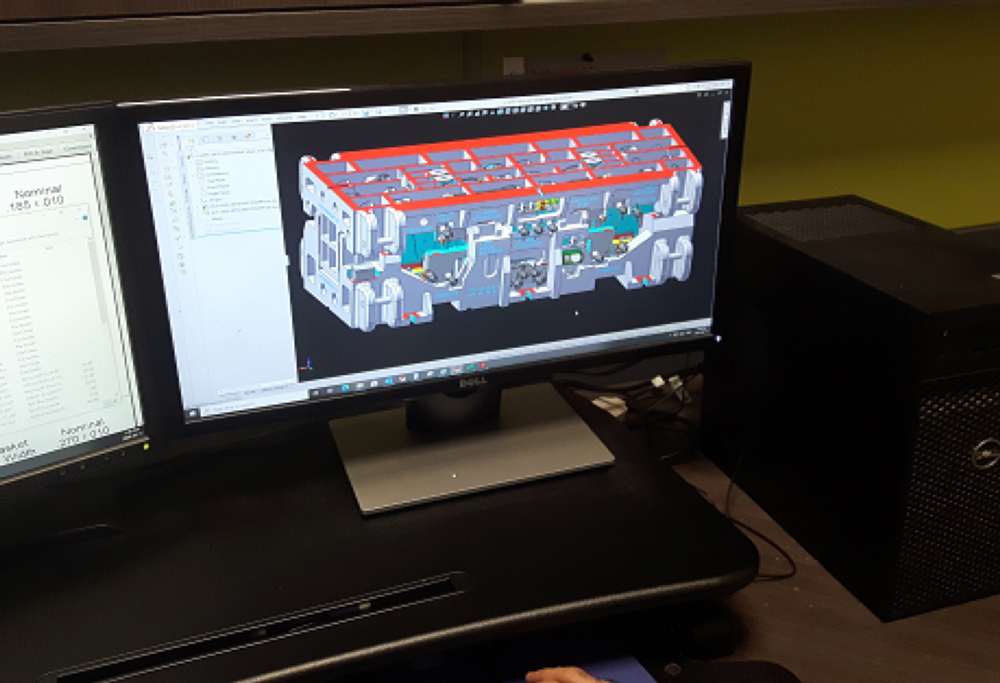

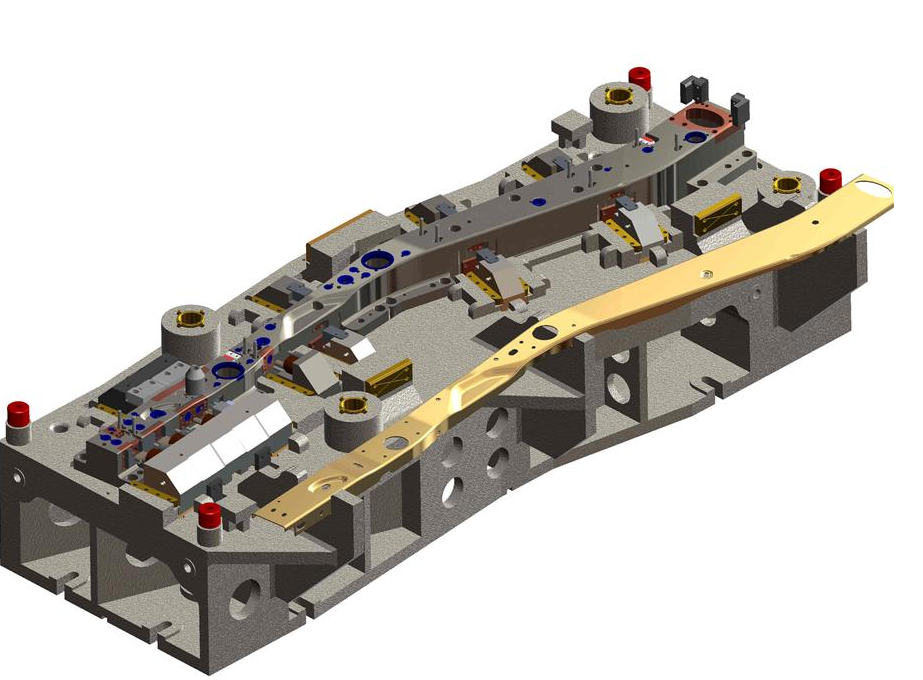

While die engineering and design may only represent a small portion of the total die cost, it can impact the majority of the overall cost, particularly if it isn’t done right. MTD engineers have decades of experience designing large and complex dies and keep a toolbox of some of the industry’s most sophisticated software to generate virtual die models & simulate die tryouts. With over 40 years of tool build innovation, supported by the latest engineering tools results in our best-in-class speed to market. Advanced engineering tools are utilized to improve accuracy and reduce trial and error. Tools such as stamping simulations, solid modeling, FEA simulation, and CNC machine coding all accelerate the development curve.

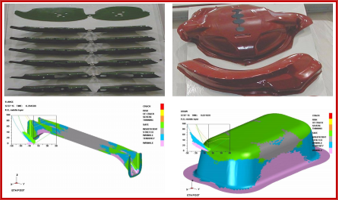

The die simulation process ensures that the production material, product geometry and tool process will withstand the rigors of the production process. Examples of problems areas commonly addressed during die simulation are thinning, fracturing, compression, stretch, wrinkling, trim line optimization and spring back. MTD also provides product design services in CAD, typically a service addressing product feasibility issues during the simulation process. This technology allows us to test and validate the complete die design prior to ever building a tool. MTD 3D CAD Modeling ensures the most efficient & total cost effective process of designing a robust and production-ready metal forming die.

The experience MTD has with all types of dies including transfer, line, progressive, blanking and hot forming, our highly skilled design engineers can create processes for unique tooling situations. MTD die design services shorten lead times, maximize material utilization, eliminate waste, maximize production speeds, reduce maintenance and improve the overall quality of the part product and tooling.

Our vertical integration supports a rapid response from concept to functional model.

Our Engineering tools include:

- Solidworks

- Rhinoceros

- Catia

- Unigraphics NX

- Finite

Experience in designing several types of dies among them are…

- Transfer Dies with Automation

- Line Dies

- Progressive Dies

- Blanking Dies

- Hot Forming Dies

Part simulation & die design